More Helpful Content

Choosing the best type of inventory management system for your company is a critical step toward financial success. You must decide based on your business’s circumstances instead of modern or popular systems. The most suitable inventory management system will improve your inventory management and then help you gain more profits as well as customer satisfaction. Go through this guide blog to discover what four types of inventory management systems and their pros and cons.

An inventory management system tracks your products throughout your supply chain, from purchasing to producing to end sales. It regulates how your company approaches inventory management. While there are some distinctions between inventory control and inventory management, the fact is that a useful inventory control system does it all by providing a holistic approach to inventory and enabling companies to use lean practices to improve efficiency and productivity along the supply chain while having the proper inventory at the proper location to satisfy customer needs. The inventory management system includes four types which are:

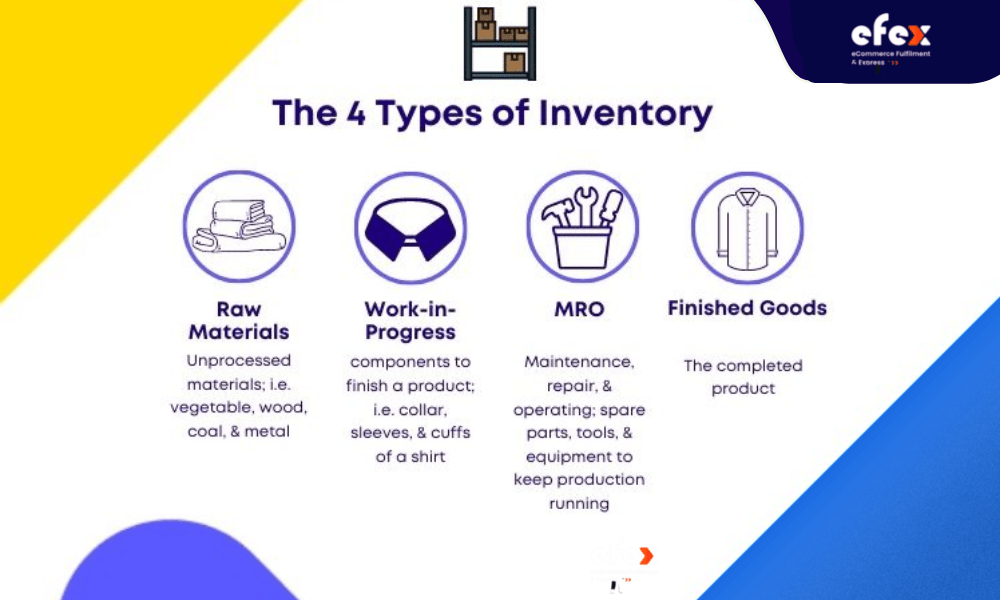

Within these systems, two types of inventory management systems employed to assist the entire inventory control process are barcode systems and radio frequency identification (RFID) systems. It is crucial to know what types of your inventory are to find a suitable inventory management system. There are four categories:

Periodic inventory is a method of inventory management that is fully based on stocktaking. Let’s stay with us to learn more about the periodic system.

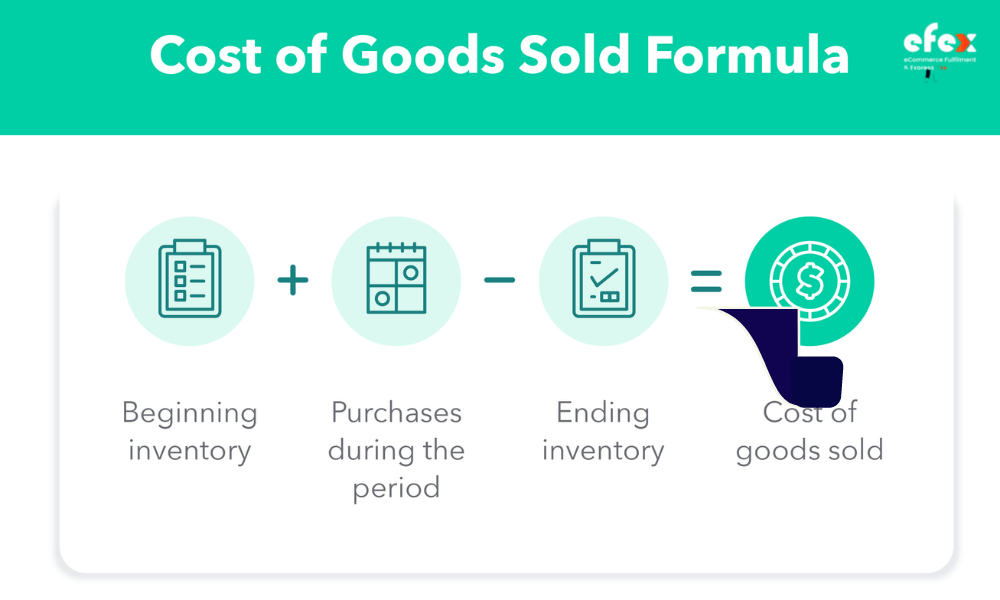

The periodic inventory system is a technique of inventory valuation for financial reporting that involves doing a physical count of the inventory at regular periods. This accounting technique begins with inventory, adds new inventory purchases over the period, and substracts ending inventory to calculate the cost of goods sold (COGS). The periodic inventory system does not track inventory daily, and they enable companies to know the beginning and ending inventory levels over a certain time. Physical inventory counts are used to track inventory in these inventory management systems.

When the physical inventory is finished, the amount in the purchasing account is transferred to the inventory account and modified to reflect the cost of the finishing inventory. Businesses can choose to compute the cost of ending inventory using LIFO, FIFO, or another technique. Remember that beginning inventory is the preceding period’s ending inventory.

The main advantages of using a periodic system are its deployment simplicity, cheaper costs, and reduced workforce requirements. It simply takes a few minutes to incorporate a periodic system into your company. Simple counts on legal paper will serve for gathering product data, particularly if you only sell a few items. A simple count during the day or week is frequently sufficient for a small company to gain a good trip on their inventory. It implies that no expensive or complex technology is required. Only the most basic information collecting instruments are a pen and paper.

One significant disadvantage is that you only gather minimum information, generally simply a discrete product count. You also do not gather or publish this data in “real-time”. You update inventory levels at specific intervals rather than when you acquire or sell them. In reality, you will not have much data to work with if you need to trace your items from start to finish or analyze shortages or overages. You cannot always determine the root of problems. However, there are other drawbacks that you should consider:

The periodic inventory control system is better suited to small firms with a limited number of SKUs that are not concerned with expanding their business over time. Any business may use a periodic system since it requires no additional equipment or code to function and hence costs less to develop and maintain. Furthermore, when time is limited, or staff turnover is significant, you can teach employees to perform simple inventory counts. Besides, if you handle your supply chain process, sell a few items, and keep an eye on your goods as they pass through your company, you may also employ a periodic system. A periodic technique will be ineffective if you need to examine missing inventory or imbalanced quantities.

Companies have to manually import the number inventory into the program at a specific period. Thus, the system necessitates keeping separate accounts for initial inventory, acquisitions, and on-hand stock. After you have acquired your ending count, calculate your cost of goods sold by taking the beginning inventory costs for a period, plus the cost of inventory acquisitions over the interval, and remove the cost of your remaining inventory.

👉 Read More: Periodic Inventory System Calculator: All Formula

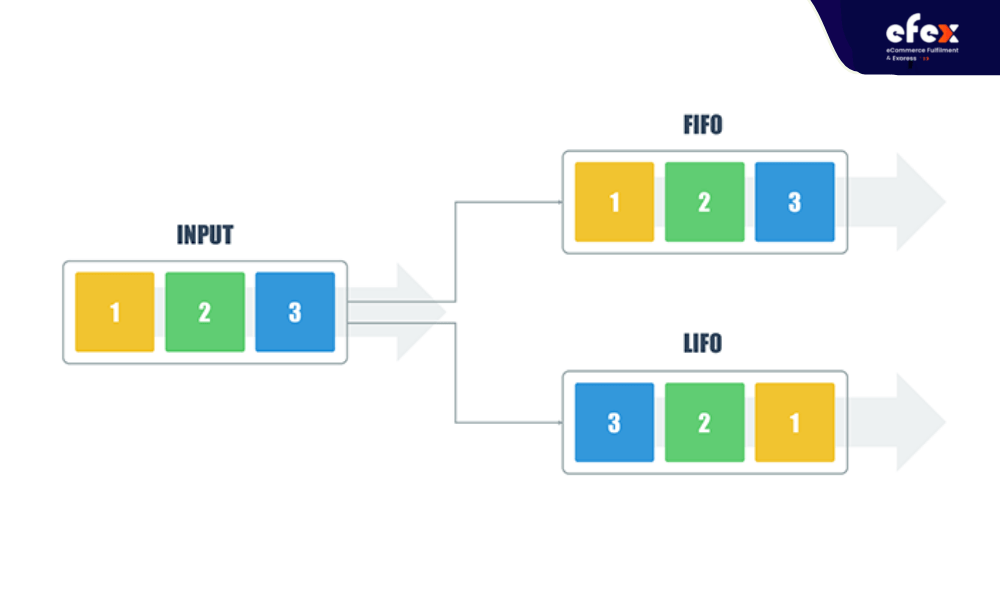

To keep track of sales, you have to compare reported sales to the beginning and ending counts at the end of a period. Since the numbers are not adjusted until you have your finishing counts, it will not directly impact your inventory account. In the periodic inventory system, there are three frequently used valuation methods, including first-in, first-out (FIFO), last-in, last-out (LIFO), and weighted average costing (WAC). The specific identification valuation method is also used but is less common than the other ones.

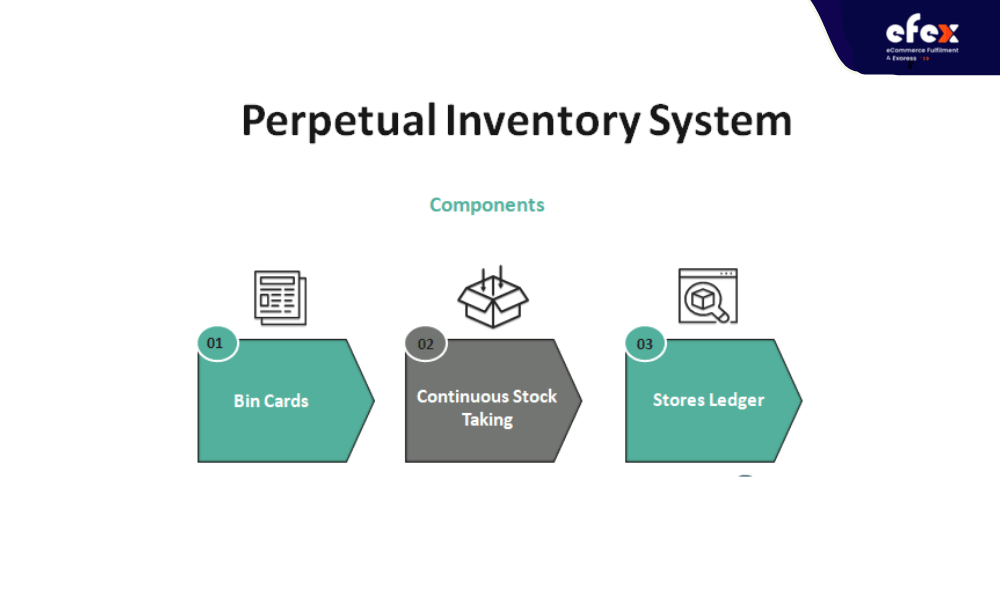

Another type of inventory management system is the perpetual inventory system which is the favored accounting approach for industry leaders worldwide, but it requires a suitable technology foundation to be implemented inside.

A perpetual inventory system is software that constantly gathers data on a business’s products. The system allows you to track every transaction, including sales and purchases in real-time. It also keeps track of all essential product details, like storage location and physical measurement. A perpetual inventory system is more detailed and comprehensive than a periodic system. It continuously updates inventory accounts and records for additions and substractions as inventory items are acquired, sold from inventory, transported from one place to another, chosen from inventory, and destroyed.

👉 Read More: What Is The Difference Between Periodic And Perpetual Inventory Systems

In many aspects, a perpetual system outperforms a periodic one, particularly for businesses concerned with long-term viability. Using a perpetual inventory system can bring many benefits, such as:

👉 Read More: Top 10 Advantage Of Perpetual Inventory System You Should Know

Despite the many benefits that a perpetual inventory system can bring, it still has some drawbacks, but not significantly.

👉 Read More: Top 10 Disadvantages Of Perpetual Inventory System

It suits large enterprises with massive inventories. It is also suitable for small to medium-sized companies that are developing and require scalability. Besides, the perpetual inventory system is used for large corporations that have trouble executing the cycle counts. Moreover, a business that owns multiple retail locations may find it easier to maintain inventories when a product database is kept up to date through a perpetual system. Other companies that require permanent inventory concentrate on drop-shipping, in which producers ship to consumers directly or in trade and distribution. The merchandise at these enterprises is constantly changing, and there are also continuous returns and exchanges. Knowing which stocks are accessible at any time necessitates a perpetual inventory system.

👉 Read More: Lifo Perpetual Inventory Method: Formula And Example

👉 Read More: Fifo Perpetual Inventory Method: Formula And Example

👉 Read More: Perpetual Inventory System Calculator: All Formula

First, you must install a point-of-sale system (POS). A POS helps you capture transactions from all retail channels in real-time and transmit the data to an integrated inventory management system. For example, when you are in supermarkets, you can see cashiers scan products’ barcodes, and the computer promptly recognizes the goods.

Next, you have to update the cost of goods sold to the system, which can improve financial reporting through purchase invoices and transactions. Then, the POS system will modify the reorder points by sharing transactional data with inventory management and ordering systems to keep adequate inventory levels, which will help businesses prevent over or under-ordering items that can limit revenues.

After that, low inventory levels can be automatically triggered by connecting all management solutions and generating a new purchase order. Employees can then evaluate and approve the request before it is forwarded to the provider. Finally, employees must integrate received items by scanning the packages when inventory shipments arrive at the warehouse. This combines the amounts into all sales channels, allowing clients to start buying the items.

Manual inventory, like its name, shows that you have to update information related to products in your inventory manually. Despite that, it is still useful in some situations.

The manual inventory system is a technique that manually records all data on inventory sheets. It is an old approach that many people still use today. In the manual inventory system, each record is manually maintained and updated by an employee who tracks everything, which raises the incidence of human mistakes. Furthermore, this technique can lead to data loss since inventory sheets may be ripped down over time, changed, or destroyed. [caption id="attachment_4356" align="aligncenter" width="1000"]

Although this is an old technique, there are still advantages that those modern techniques may not have.

Manual inventory only works well when your business is small with not too many goods. If you are running a medium-sized business above or want to expand your business size, it would not be a great technique for many reasons:

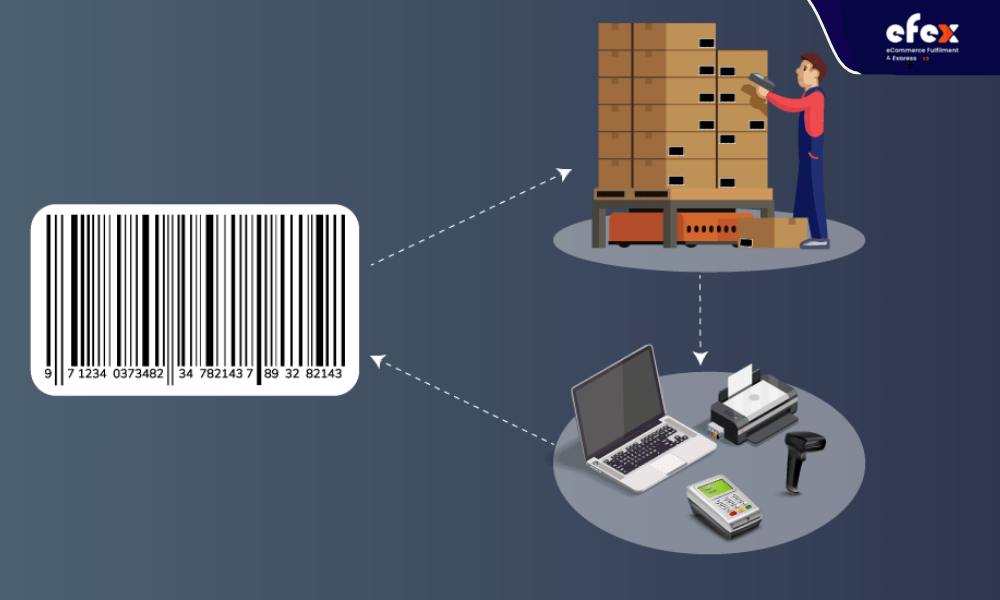

Inventory management solutions that use barcode technology are more precise and efficient than human operations. Just go through to learn more about the barcode system.

A barcode is a one-of-a-kind symbol containing numbers or text, similar to what you may find on grocery merchandise. The graph visually depicts data. When scanning a barcode, the product’s details are immediately sent to a computer. Barcode includes two types which are 1D barcodes and 2D barcodes.

👉 Read More: Barcode Inventory System: Its Benefits & How To Use It

A barcode system allows companies to monitor inventories more quickly and easily. When items contain barcodes, they are scanned using a portable mobile device and linked in real-time with inventory management software. When used with an overall inventory control system, barcode systems automatically update inventory levels when workers scan them using a scanner or mobile device.

The advantages of adopting a barcode inventory system in your inventory system are numerous.

👉 Read More: How to Create a Barcode Inventory in Excel

👉 Read More: Top 10 Barcode Inventory Management Software in 2023

Despite the useful and cost-effective barcode system in the inventory management system, there are some disadvantages that you should notice:

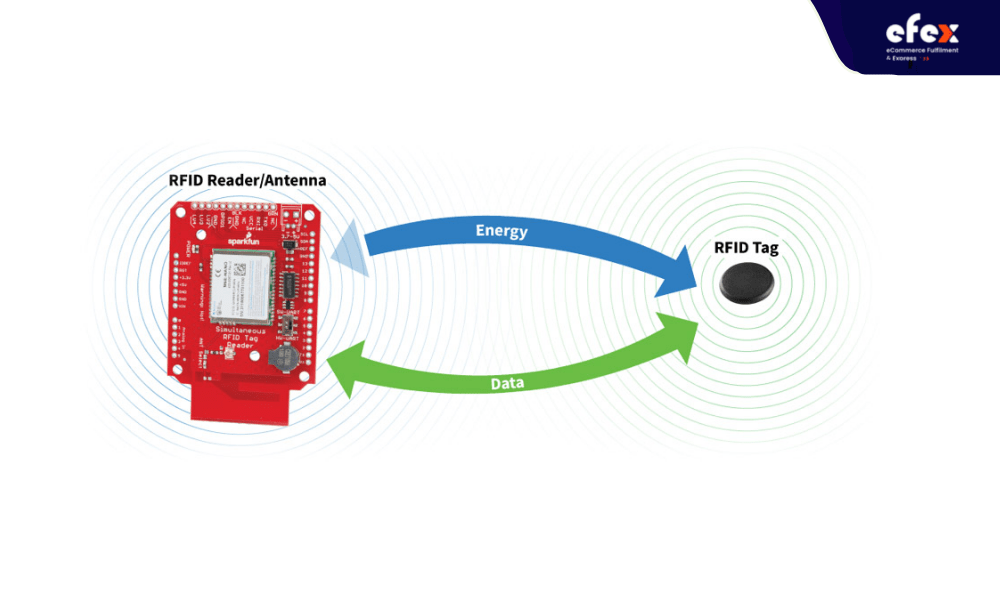

Radio frequency identificatio system is becoming more widespread these days.

Radio frequency identification is an active-and-passive technology that helps to manage inventory movements by using radio waves. Active RFID technology is defined as fixed tag readers strategically placed throughout the warehouse, while passive RFID refers to portable readers. The RFID tag is a tiny microchip typically connected to an antenna and can store various data information related to a specific product.

Tags are encased in paper, plastic, or other similar materials and are attached to the item or its wrapper, a container or pallet, or even a delivery truck or van. The radio frequency identification reader interrogates tags and takes responsibility for transmitting and receiving radio signals from and to the RFID tag. Then there will be specialized computer software to compile and analyze the information gathered by the reader. Readers can be put at various locations across a warehouse to track when products are moved.

RFID enables a company to identify specific items and features and track them from manufacture through point-of-sale.

Using RFID technology in inventory management has supported businesses solve many problems and boosted efficiency and precision. Let’s check out what benefits the RFID can bring to us in the below part.

However, neither systems are perfect. The RFID still has some certain drawbacks, which are:

In conclusion, we hope this blog will provide you with the most fundamental and detailed knowledge about the four common types of inventory management systems used in inventory management today. Understanding these systems will help you a lot in managing your inventory. You've found this article so helpful? Do not forget to follow our Fanpage and website to read more interesting articles!