More Helpful Content

It's not simple to choose the ideal inventory control way for your business. The more quickly your business expands, the more challenging inventory control gets. That is why laying a strong foundation from the beginning is so important. Let's go through 15 techniques of inventory control, processes, and best practices with us in this article straight away.

This inventory technique is built on the concept that purchasing and transporting products in large quantities is often inexpensive. Bulk transportation is one of the most widely utilized methods in the industry, and it can be applied for items with high consumer demands. The drawback of this technique is that you will have to pay extra money on storage, while it is often offset by the amount saved by purchasing high quantities of items and distributing them rapidly.

- See more: Order Management System: Definition, Process, And Value

- See more: Order management system for eCommerce: Definition, Key Effect, Benefit

Pros

Cons

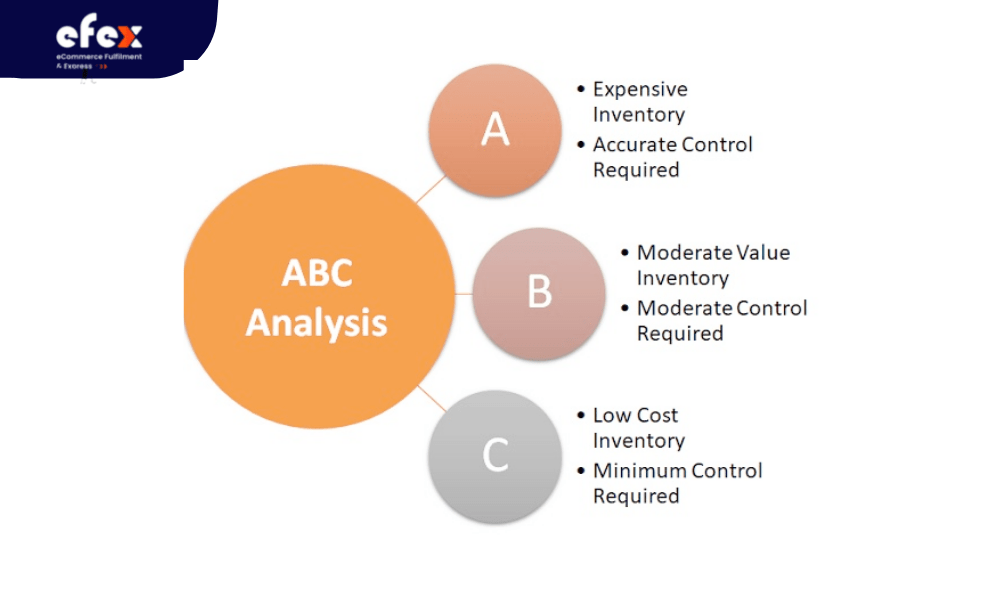

ABC inventory management is the system for sorting commodities in order of priority with the concept: A is by far the most valuable and C is the least. Not everything is made equal, and more attention should be paid to more popular items. Despite no strict and quick rules, ABC analysis focuses on annual consumption counts, inventory value, as well as cost importance.

When selective financial allocation, inventory control technique, and human resources are needed, the solution is to operate each group independently.

Pros

Cons

The technique of back-ordering mentions to a business's decision to handle orders for products that are out of stock and take payment for them. For most companies, this is a good thing, but it can also become a logistical nightmare if you're not well-prepared. If there's an only one unavailable commodity, creating a new purchase order for that goods and notifying the shopper once the back ordered product will come is all required.

👉 Read More: 15 Useful Tips To Improve Inventory Management

When you're handling tens, if not hundreds, of various sales each day, problems start to occur. Enabling backorders, on the other hand, generates profits, so it was a fine balance that many businesses are willing to do. Overstocking may not be a solution for small companies. In this situation, the item's "Buy now" button may be labeled "Pre-order" or "Get yours when it comes back in stock." Customers will have a realistic expectation that it will take a little longer to arrive as a result of this.

Alternatively, several companies use a "no-stock" method, in which they only accept backorders until they've made enough sales to place a huge bulk order with a supplier.

Pros

Cons

JIT (Just In Time) management reduces the number of stock levels that business keeps on hand. Since you only purchase inventory a few days before it's needed for delivery or sale, it's deemed a risky approach. By maintaining inventory level minimal, as well as preventing several situations where deadstock (basically frozen capital) sits on shelves for months, JIT lowers inventory holding expenses.

Organizations, on the other hand, should be exceedingly adaptable and able of tolerating some far faster manufacturing cycles. If you're thinking about implementing a Just-in-Time inventory management system, examine the following questions:

Pros

Cons

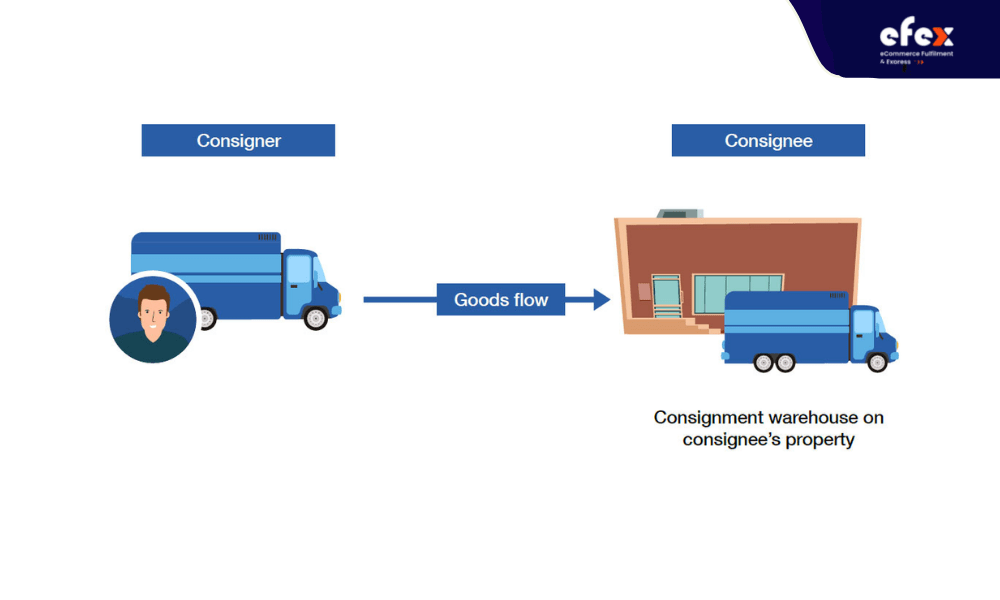

A wholesaler places merchandise on consignment with a retailer but retains ownership of the goods until it is sold, at which stage the retailer buys back the spent stock. From the business's standpoint, selling on consignment entails a high amount of demand unpredictability, as well as a large sense of trust from the wholesaler's view. Selling on consignment has various advantages for retailers, including the possibility to:

While the wholesaler bears the majority of the risk in selling on consignment, there are still a number of possible benefits for the vendor:

If you're planning on selling on consignment as a retailer or wholesaler, be sure to spell out the following terms:

This inventory control method completely removes the cost of storing inventory. You can directly pass customer orders and delivery information to your manufacturer or wholesaler, who will subsequently ship the items if you have a dropshipping relationship.

Cross-docking is a procedure similar to dropshipping in which commodities are unloaded directly onto outbound trucks, trailers, or rail cars from incoming semi-trailer vehicles or railroad cars. Basically, it means that products are transferred immediately from one transport vehicle to another with no or little warehousing.

👉 Read More: 15 Best Practices For Inventory Management

It's possible that you'll need staging spaces where inbound items are sorted and stored until the outbound delivery is done.

For cross-docking to function, you'll also need a large fleet and network of transport vehicles. Of course, you can still keep tracking your shipments on your partner's system if they have it.

Counting little levels of stock on a certain day without having to undertake a full manual stocktake is known as cycle counting. It's a form of sampling that lets you check how closely your inventory records match what you actually have on hand.

This strategy is used in many firms' inventory control methods since it ensures that consumers get what they want. When they want it while keeping inventory holding expenses to a minimum.

Pros

Cons

Material Requirements Planning (MRP) is a strategy of inventory control in which producers order goods based on sales projections.

The MRP system combines data from many areas of the organization that have inventory. The manager would carefully make an order for fresh inventory with the material suppliers based on the data and market demand. MRP allows companies to see the inventory they need to satisfy demand, allowing them to manage the inventory level and production schedules. Companies with low visibility and response lack this insight, which can result in:

Manufacturers depend heavily on MRP as a supply planning system for planning and tracking inventory, scheduling, and production, but MRP is also used to balance supply and demand in a variety of other industries.

Pros

Cons

Businesses must ensure to enter the right inventory availability, time to perform a subassembly, waste calculations, and vendor lead times. Otherwise, the production schedule will be inaccurate—if the data isn't provided in the inventory record, bill of materials, and master production schedule, an MRP won't be able to specify the production build timetable and materials necessary.

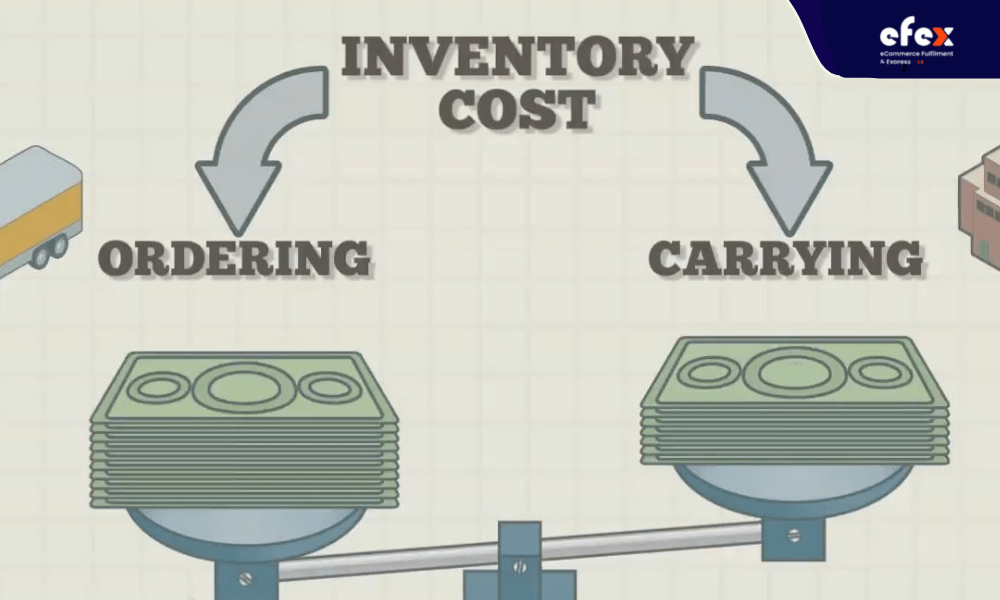

The Economic Order Quantity (EOQ) method involves determining how much inventory the business should order at any given time and when the order should be placed. Ordering too much can result in excessive holding costs and divert resources away from other business operations, such as marketing or R&D.

👉 Read More: 15 Vendor Management KPIs You Should Know

EOQ is a key metric for businesses' sustainability to grow sales or cut costs. When the inventory reaches a minimal level, the store manager will reorder it. The EOQ model aids in the reduction of ordering and carrying costs incurred throughout the order placement process. The EOQ model allows the business to place the correct amount of inventory.

Pros

Cons

A firm's minimum safety stocks are the number of inventory kept on hand to avoid a stock-out situation. For instance, if an organization's total inventory is 18,000 units, it will place a new order when the inventory reaches 15,000 units. As a result, the 3,000 inventory units will be included in the minimum safety stock level.

Vital Essential and Desirable (VED) is mostly used by enterprises to keep track of inventory spare parts. For example, crucial parts that are both expensive and necessary for production demand a larger amount of inventory. Others are critical spare parts whose absence could cause the manufacturing process to slow down. As a result, such inventory must be maintained. Similarly, an organization can keep a modest quantity of inventory on hand for desired items that aren't used frequently in manufacturing.

The Fast, Slow & Non-moving (FSN) method of inventory control is quite effective in preventing obsolescence. All of the inventory isn't used in the same order; some are needed regularly, while others aren't. As a result, inventory is divided into three categories: fast-moving inventory, slow-moving inventory, and non-moving inventory, according to this method. The usage of inventory is used to make an order for new inventory.

Pros

Cons

After each buying, sale, withdrawal, or other activity, a perpetual inventory system maintains a constant and updated record of inventories. A perpetual inventory system is one that automatically updates inventory levels on a regular basis. This system is heavily dependent on automation to track purchases and sales in real-time and update inventory records. As a result, this method enables companies to maintain a real-time inventory count.

Pros

Cons

Lean manufacturing is a bundle of controlling techniques that may be implemented in any business. Its purpose is to increase efficiency by removing waste and non-value-adding operations from day-to-day business.

Pros

Cons

Lean Six Sigma improves on Six Sigma's tools but focuses more on boosting word consistency and business flow.

Pros

Cons

👉 Read More: 20 Important KPIs For Inventory You Need to Notice

Because inventory is your business's most valuable asset, you should safeguard it and nurture it in the right direction in order to optimize cost and make money. You'll never get ahead if you don't use techniques of inventory control. As a result, businesses should take all necessary precautions to ensure that inventory control systems are always up to date. You've found this article so helpful? Let's forget to follow our Fanpage and website to get many interesting articles!