More Helpful Content

Ever wondered how online retailers get your favorite products to your door so quickly? It's all thanks to order fulfillment. But what is order fulfillment exactly? This article will break down the complex process, from the moment you click "buy" to the arrival of your package, revealing the strategies and logistics that make it all happen. Get ready to dive into the world of order fulfillment and discover the secrets of a seamless shopping experience.

What is order fulfillment? Order fulfillment refers to the process of receiving, processing, packing and shipping orders to customers.

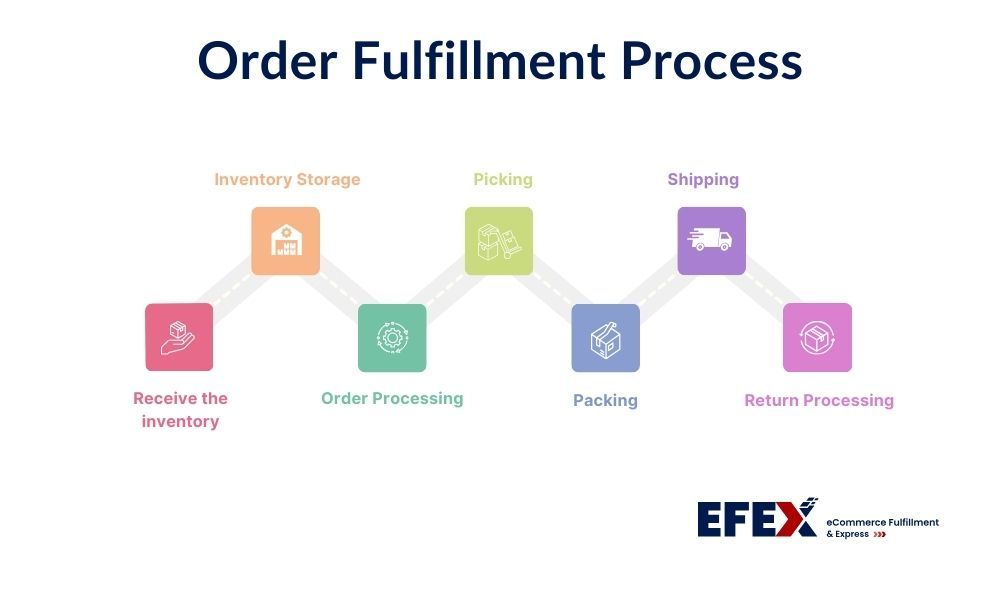

Each industry will have its own definition of order fulfillment. Despite that, the order fulfillment process will most likely have these components:

>> Learn more: What is eCommerce Order Fulfillment?

Each merchant may want to take care of the fulfillment process themselves or outsource this process to a 3PL (Third-Party Logistics Company) who would then handle the receiving, storing, staffing, and working with the delivery company. Choosing to work with 3PL companies is a great way for merchants who want their business to scale effectively.

Companies earn profits by selling their goods, services, and products to customers or other businesses. Suppose you want your products to come to your customers without any trouble. Your company must have a specified order fulfillment process with detailed steps to carry out the whole process to bring the products to customers.

The company must illustrate the process in an order fulfillment flowchart to help your employees understand how your order fulfillment works to follow these steps to help the company be better.

An effective order fulfillment process will bring reputation, profits, and clients to the company.

The order fulfillment process usually occurs in one or more distribution centers. It normally includes inventory management, supply chain management, order processing, quality control, and support for customers who need to report problems or exchange or return products.

The order fulfillment flowchart below shows the standard order fulfillment process steps you should consult.

The initial stage of order fulfillment involves receiving inventory from suppliers, third parties, or warehouses. This process requires meticulous verification to ensure the quantity and quality of goods align with the order. Careful counting and inspection are crucial to confirm the accuracy of the received goods and identify any potential damage.

After confirming the quantity and quality, each item is assigned a unique Stock Keeping Unit (SKU) or barcode. This vital step allows for easy tracking and management within the warehouse management system. SKUs are then integrated into the order fulfillment software to streamline the entire process, facilitating tracking from receipt to storage and retrieval.

This foundational step lays the groundwork for efficient order fulfillment, ensuring that inventory is correctly accounted for and ready to be processed for customer orders.

This step of the order fulfillment process is vital because it directly affects picking speed. Once the warehouse has received the inventory fully, they would start storing their inventory.

How the warehouse stores its inventory also requires you to plan ahead to achieve lean efficiency. Business owners and warehouse key persons should never gloss over this aspect since how people organize their storage space will determine the speed and accuracy of picking.

Most warehouses should benefit from organizing their goods by SKU. This helps ensure that the right items can be easily picked and moved to the next steps. This simple technique would also eliminate human errors and make sure the picking and packing are processed quickly.

Any merchants who have worked with a big amount of SKUs or product lines will know that failing to organize’s one inventory is a deadly mistake. Don’t wait until a severe mistake happens before you start organizing your warehouse properly.

The order processing system takes responsibility for managing all the order processes. It dictates the picking or packing status of the products for each order.

The picking teams or robots will select items according to a packing slip’s instructions which contain specific information like product colors, sizes, number of units, location within the distribution center’s warehouse, or a list of items SKUs.

Packing is where all of the items picked in the previous steps get wrapped up so that they can spend their time in transit protected. This process requires staff to choose the right packing material based on the items being ordered. Depending on the merchandise and the goods, the packing materials and the goods could include bubble mailers, poly bags, packing tapes or air-fill, etc.

If you are handling fulfillment on your own, you should make sure that you have your ancillary material ready. These items are quite essential and would cause a huge delay if anything is missing.

There can be many ways to ship a package, but nowadays people usually expect it to be speedy and free of charge. This is where you need to pay attention and do your homework on the most suitable shipping company.

You should evaluate all of the options available when it comes to shipping. Understanding all of the available options would also help you steer your customer to the right options based on their budget and the duration they are willing to wait for their package.

If you are using a 3PL, a shipping service will pick up your order from the fulfillment center. If however, you are doing everything by yourself, you might have to visit your UPS or post office every so often so that your order reaches the clients at the estimated arrival time.

Once the order has been taken care of by a carrier service, your clients should be notified of the tracking number so both parties can keep track of the delivery status.

The return processing does contain quality managing checks and sorting returned products. Returned products are returned to manufacturers for a distributor refund, restocked, or sent to a recycling center.

Online shopping does not like traditional shopping, where customers can see the merchandise through images and videos. It causes an issue that many customers are not satisfied with the products once they receive, and want to return the products or exchange others.

Therefore, return processing can not be underestimated within the order fulfillment process. A reasonable return policy will affect the customer’s buying attitude for the following time.

There are a lot of order fulfillment challenges in the order fulfillment. It contains these four main challenges expanding from inventory management, demand planning, logistics planning to supply chain execution.

The issue that most businesses have to face is running out of stocks. It will lead to failures in managing customer experience and customer dissatisfaction and harm the company's reputation. How disappointed would customers be when the products they want to buy are always in the out-of-stock status?

However, if the reasons for shortages and delays are caused by nature, like weather events and natural disasters, it would be different. Customers tend to forgive for the shortages in situations like that.

Stocking a large amount of readily available is not a good idea and is even risky.

First, it will increase storage and carrying costs because you need to have enough space to store all those stock.

Second, customers’ demands fluctuate constantly, so if the company store too many stocks, it can lead to the problem that customers may no longer need them before the company can sell their products.

It is critical to carefully forecast and plan for demand levels to keep an acceptable amount of goods in stock without storing too many or too low products.

If a business does not have careful logistics planning, it would cause many problems and damage its reputation, future sales, and profits.

The business should prepare logistics plans for various situations. They can be any problem like wet packaging, broken items, slow or missing deliveries, and so on during the order fulfillment process.

Creating a supply chain execution strategy requires the companies to evaluate the cost versus benefit tradeoffs regarding operational choices. There are many ways to do that.

For example, a company can choose a distributor to gain price breaks or priority status. But the risk is that if the vendor gets into trouble, the company will not be able to adapt to customers’ needs.

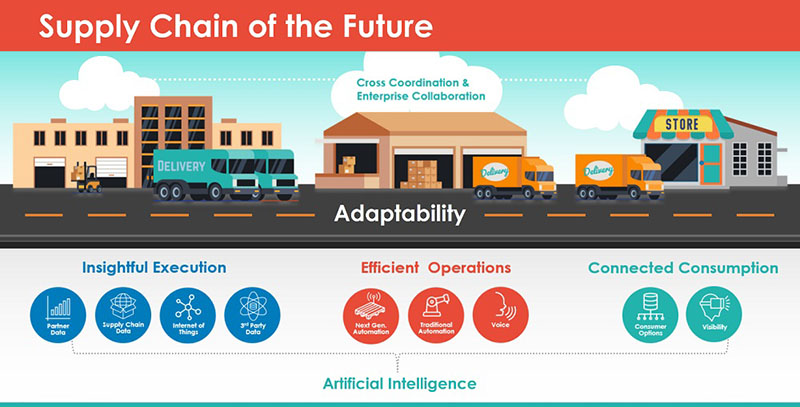

Supply chain execution plays a critical role in the supply chain. It helps the company manage material, track the physical status and movement of goods, track data feeds and data shares, and control financial transactions among all parties.

Today, supply chain execution uses numerous applications like warehouse management, transportation management, order management, inventory management, and logistics software.

No order fulfillment process works for every business. Whether you choose a third-party logistics company or an outsource company or use a hybrid warehouse fulfillment model, your goal is to find the right process that meets your company’s demands and your customers’ expectations.

Many people may think this is a straightforward task, but you have to evaluate several factors when selecting a logistics business. A suitable shipping company for your company will help you improve the order fulfillment process and picking accuracy.

First and foremost, you must be certain that the firm you select can properly deliver to your consumer base. For more details, you must comprehend the features of most of your clients' locations, such as cities, rural, locations that are difficult to reach, and more.

Then, you should view that firm’s reviews and ratings to see what customers said about it and whether it can send extra-large shipments as well as extremely small and fragile things swiftly without damaging or misplacing them. You can research many logistics brands on the market and compare them for more options. You can also chat with other company owners about the transporting providers they are using.

When buyers make an order on your online stores, you should keep in touch with them from when they place an order until they receive their products, even after they receive them for a couple of days or a week. Since customers like to be taken care of and are interested in knowing the status of their orders, providing your consumers with regular information on when they may receive their package not only makes them able to track their orders and create customers’ sympathy with your company.

Despite your fast shipping or quality products, nobody likes a complicated or frequently-have-error order system. You must often check to ensure that your computer tracking systems are functioning properly and make sure that the time an employee in your warehouse receives an order should be as short as possible.

Besides, you should speak with your staff to see whether they see any areas that need improvement. If any squeaky wheels emerge throughout this procedure, address them as quickly as possible.

Making everything appear to be running smoothly in the warehouse is one of the rules that any warehouse must follow if you want to improve the order picking accuracy. There is always an opportunity to improve it better. Creating a simple and transparent strategy for storing goods will help you increase the pace of your shipping and your staff’s productivity. This will assist your warehouse staff in locating an item quickly and save more time in sending it.

Besides, slotting inventory can support you in enhancing throughput and accuracy levels by storing comparable sorts of inventory goods. You can classify goods based on dimension, seasonality, frequency of choosing, and other factors. A well-marked warehouse also supports you with your inventory management and theft prevention.

Modern buyers appreciate comfort and convenience. Despite some people prefer to order in person, most prefer to place an order via technology. Companies normally offer multiple ways to take orders, such as in-person, internet, phone, email, cellphone app transactions, and social media. If your company does not provide one of these ordering alternatives, you should consider your clients’ ordering options.

Classifying your inventory might help you determine which sorts of items are selling rapidly and which are not. To keep up with buyers' demand, you would have to restock the best-selling items more frequently. Moreover, you should also keep these items in a more conveniently accessible position than other items to pick things up and execute orders as soon as feasible, improving the picking accuracy.

Another method for categorizing your inventory is to divide orders into orders that have not been fulfilled, orders that have begun but have not been completed, and orders that have already been fulfilled. You can filter out orders you have completed and concentrate on those needing to be shipped. It simplifies the process because you will not have to waste time trying to keep track of the progress of numerous orders. Thus, you do not need to focus on tracking your orders manually when you use order management.

Quotes are a pricing estimate for a product or service, while orders are “contracts” between your company and buyers. A quote is not the final pricing, but it is quite close. You can provide free quotes to prospective consumers, who can decide whether to accept them. It may be the initial stage in a sales transaction involving services or high-end objects that do not have a visible price tag.

The consumer will come to your store, visit your website, or chat with you directly about a service or product, and in exchange, they will receive a price quote. That quote might be solid or flexible, depending on your business. In any situation, the customers may or may not accept the estimate.

In contrast, an order displays what the consumer has requested from you and what you have promised to provide. It contains the whole amount of money the consumer will pay for your goods or service. It explains the pricing and terms necessary and is frequently delivered to buyers through email.

In other words, the consumer has stated that they want to buy something from you but that either the store cannot supply it or they do not wish to take ownership at that moment. If a client requests a specific item that you do not generally keep in stock or a large quantity of an item that you do not normally carry, you will make an order.

Allowing users to print select lists or see them on mobile devices can help you avoid costly mistakes. This way helps pickers double-check orders to confirm they are selecting, packaging, and shipping the proper things to the correct buyers. It also saves pickers time that they would spend on rechecking lists and goods manually.

To minimize costly disruptions in order fulfillment, you should optimize your picking system. You can do that by appropriate labeling all of your stocks and utilizing order management software to find and monitor things. You will see the picking process improves clearly and speedier.

Maintaining transparency throughout your firm is necessary when you have many sales channels. Everyone participating in your stock levels, customer services, sales activity, and supplier updates should be on the same page. End-to-end visibility will assist in more precise order fulfillment and improved customer satisfaction. It will also expedite the entire procedure.

It is an important method to help you keep tracking your inventory and fulfill orders from many locations. For example, if you have an online store, a brick-and-mortar store, and a warehouse where you store your goods, multi-location management tools and support will prevent you from getting confused with orders and avoid creating bottlenecks during the fulfillment process.

Integrating multi-location inventory management software into the order fulfillment process and warehouse management helps the inventory and production across numerous sites to become more convenient and easier than ever. Thus, you can check that your inventory counts are up to date and that all sales are appropriately monitored across several locations.

Flexibility is one of the factors that can assist you in creating stronger customer relationships. You will gain confidence and loyalty by providing numerous delivery alternatives, enabling consumers to adjust their orders, and accept refunds and returns. Let’s consult the following ways to help your company stay adaptable during the order fulfillment process:

Order fulfillment has many steps and involves many moving parts. However, there is no singular one size fits all solution for every situation. Each enterprise and organization will have to figure out the most suitable strategies.

Most businesses will start out using their in-house resource to handle all of the orders. This usually happens when a business has more time on its hands than the available cash. However, if your business is growing at a two-digit scale. It may be time to rethink your order fulfillment strategy. Two reasons most often cited when business owners decide to switch to the outsourcing model are spending too much time or spending too much money.

If all the order fulfillment steps are taking up your time, affecting your mind space, and limiting your ability to take care of other facets of the business then you may consider a 3PL. Another scenario is that your warehouse location is too far away and there is not enough warehouse location to keep your shipping cost at an acceptable range.

- See more: Order Fulfillment Cost: All of the Fees You Need to Pay

Working with a 3PL that can help you leverage multiple warehouse locations and discount shipping costs will be a reasonable choice for your bottom line and customer satisfaction. Currently, Efex also provides All-in-one Ecommerce Fulfillment Solution to unbox all your worries and help your business thrive. You can refer to more information about EFEX here!

Order fulfillment is a complex process that requires careful planning and execution across receiving, warehousing, order processing, picking, packing, shipping, and returns. As outlined, there are many steps and challenges involved in getting orders efficiently from warehouses to customer doorsteps. Companies must balance inventory, demand planning, logistics, and supply chain execution.

When business growth makes in-house fulfillment overly time-consuming or costly, outsourcing to a 3PL like EFEX can be prudent. EFEX provides e-commerce order fulfillment solutions to handle warehousing, order processing, packing and shipping so companies can focus on other aspects of their business. With expertise in streamlining fulfillment and leveraging multiple warehouses for efficiency, EFEX is an option worth exploring for any merchant seeking to optimize your order fulfillment process!