More Helpful Content

Business nowadays is difficult to forecast and frequently involves competition. Current inventory management techniques, as well as the inventory management software that supports them, have grown in value and demand as storage methods have improved and organizations have gained a competitive advantage.

Vendor-controlled inventory falls under this category and is an excellent technique to keep a company's day-to-day operations functioning smoothly. Buyers and sellers agree to share a little amount of risk in exchange for a much larger gain in vendor-managed inventory. It's a win-win situation when done correctly. Here's what is vendor inventory management definition, how it works, and why it's so advantageous to two parties at once.

Vendor-managed inventory (VMI) refers to a supply chain arrangement in which the manufacturer or supplier takes control of the seller's or retailer's inventory management actions including managing, maintaining, and optimizing their inventory.

👉 Read More: What is Inventory Management? How Does it Work?

In other words, this indicates that the upstream agency is in charge of the downstream agent's inventory. Managed inventory, continuous replenishment plan, or supplier-assisted inventory replenishment are all terms used to define this type of vendor management inventory agreement.

VMIs are those that are owned by the vendor but are kept on the premises of the buyer or retailer. It's a type of consignment inventory in which a merchant entrusts their inventory to the protection of others while holding ownership. So, how does a vendor-managed inventory system perform? Here's how it works with a vendor-managed inventory system:

👉 Read More: 15 Vendor Management KPIs You Should Know

👉 Read More: 20 Important KPIs For Inventory

You Need to Notice Other terms of the contract will specify whether the buyer will pay for the inventory when it is acquired or when it is sold to the end-user. Also, how will surplus inventory be returned?

Vendors who know the time to replace their purchasers' inventory have strong VMI partnerships. The key to this is for purchasers to share their sales and demand prediction information with their vendors.

In general, for a strategy to be successful, it must include a large number of use cases and functional situations. VMI solutions work efficiently when the inventory supplier has a warehouse or production facility close to the customer. That's one of the numerous reasons why production suppliers tend to cluster in places with a big client base.

For example, an airplane manufacturer may be adjacent to inventory suppliers such as a metal sheet maker, tire supplier, or bracket manufacturer. Businesses that use this method of managing inventory should be able to do depth research on their inventory needs before approving a vendor. The buyer must do careful research in order for both parties' stock levels to be in sync.

Additionally, this also aids users in determining how much inventory needs to be held and allowed access to the stock supplier's warehouse in order to efficiently meet demand. Small businesses with basic supply chains may not have too complex inventory requirements that change primarily in response to predictable demand patterns. Mid-size and large-scale businesses with a complicated supply chain, on the other hand, may require vendor management inventory or ERP software to assist them to manage their operations.

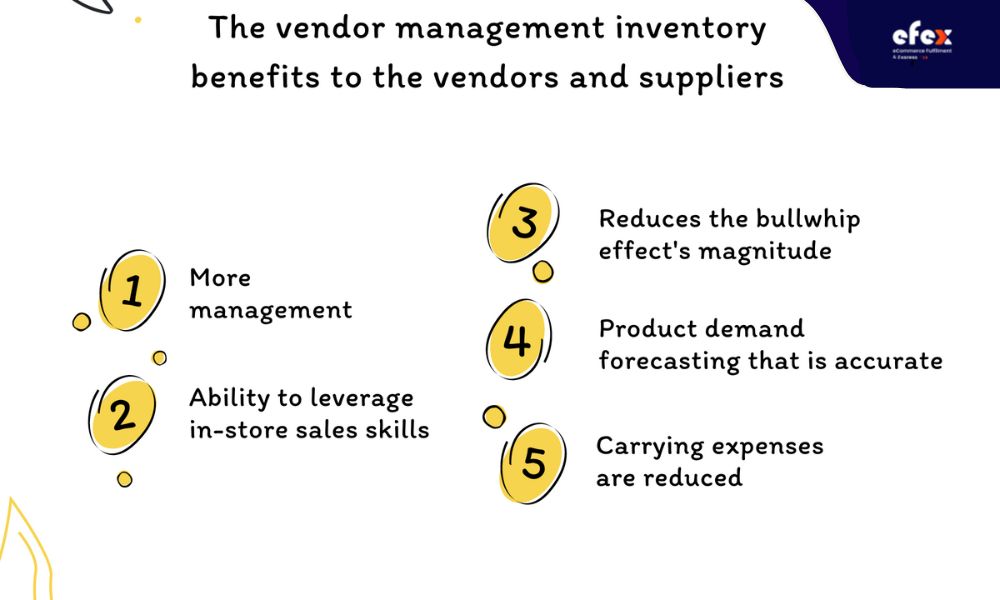

Why would a vendor be in trouble for controlling the inventory of another company? And why would a buyer surrender ownership of one of their most valuable assets, their inventory? The vendor inventory management system is a win-win situation for both suppliers and buyers when done effectively. VMI offers considerable cost savings in inventory management that benefit both parties.

When your supplier gets control of the inventory management system, they'll be able to integrate your information with their expertise in lead times to remove the need for excess inventory.

You can reduce the uncertainty around periodic random and ordering by ensuring fluid, consistent replenishment using a vendor-controlled inventory system. Because your vendors have done it before, they will always know how to balance lead time and demand.

VMI has certain drawbacks, such as requiring non-employee access to data sets and, in some cases, real physical inventory. You're also looking for a third party to keep your inventory at the optimized levels, which can be unsettling for supply chain professionals. Nevertheless, one of the most significant disadvantages of VMI is its influence on sourcing. Supply chain professionals frequently believe they won't be able to locate another source for a product managed by a reliable supplier.

If a supply chain management relies too heavily on a single supplier to manage its stock, he or she may have to accept higher pricing, lower quality, or other supplier-related difficulties. Multiple sources for a product controlled by a supplier may also be challenging for supply chain professionals at times.

As a supplier, once you can win the loyalty of customers and demonstrate your capacity to improve your customer's inventory utilizing VMI, you can be sure that you will be the product's long-term supplier. When there is no VMI effect, it is tough enough for supply chain management to participate in a sourcing operation. A VMI that is well-run makes re-sourcing not only difficult but also a low priority.

Now, let’s see a vendor-managed inventory example below! Spring Home, a fictitious home improvement shop, is used in this vendor-controlled inventory example. Assume Spring Home is a retailer of Fryst portable door locks. Fryst has a VMI deal with Spring Home. Spring Home constantly delivers Fryst data about their portable door locks sales patterns and inventory levels through EDI or online.

Fryst examines their lead times and calculates replenishment based on this information. Fryst's inventory specialist evaluates the figures and places all of Spring Home's replenishment orders. Spring Home and Fryst's effective and lucrative partnership is dependent on correct information being shared on a regular basis. It is the only way to run a vendor-managed inventory system successfully.

Vendor-managed inventory software also referred to as supplier-assisted inventory or continuous replenishment programs, aids businesses in order fulfillment and optimizing the inventory management process. Both sides share data in this type of system in order to improve consistency. Vendors, on the other hand, have the right to teach and educate their staff and associates about their inventory and how to use it.

It may be challenging for a company to find out the software with a set of the finest features, especially when you've never utilized a solution before (it'll be even more overwhelming). We've compiled a list of typical VMI features to make the process easier. Aside from this, you may seek other features that are tailored to your company's needs.

One of the critical features that VMI systems provide is the ability to estimate the exact demand for products. They assist in the projection of demand for goods that need to be produced, packaged, and dispatched quickly. It brings together the information to specific units from different companies making up your client base, allowing for more informed supply chain planning. Besides, the software also assists in identifying any underperforming stock-keeping units and preventing overstocking in the warehouse or retail store.

You can keep track of data on the items your company stores, buys, produces, or sells. The application also allows for appropriate pricing and helps keep stock levels at optimal levels all the time. Serial and lot tracking should also be included in a robust supplier-managed inventory system.

VMI solution enables data and material interchange inside an organization as well as between customers, clients, and corporate partners. Customs and tax details, inventory records, purchase orders and receipts, delivery and order status, and other information are included.

A VMI system that interfaces with various online shops, shopping carts, as well as e-commerce platforms are available. Inventory levels, methods of payment (including both cash and digital), and transportation modes and options will all be streamlined as a result of this solution. Companies can utilize warehouse management software or other stock control system to handle all items sold through a specified e-commerce shop.

👉 Read More: Top 10 Vendor Inventory Management Software in 2023

Now that you're aware of the numerous advantages of implementing a vendor inventory management system, you can go on to find software that meets your specific needs. A tip to make things easier is that you should create a list of goods that match needs that are critical to your business's operations. We hope this post has provided you with a comprehensive view of what vendor inventory management is and how it can benefit your business.

Be aware of the limitations or obstacles that this inventory management system may have, and carefully evaluate how to set up and maintain VMI at your organization. You've found this article so helpful? Let's forget to follow our Fanpage and website to get many interesting articles!