More Helpful Content

One of the pillars of a successful retail company is inventory control. Retail inventory management techniques assist retailers and e-commerce sellers in satisfying customers, reducing expenses, and maximizing profits. Then, what is retail inventory management? How to do it effectively? Let's go over this article to figure out the answer to it.

Retail inventory management refers to the process of assuring that you have the products that customers need on hand, without having insufficient or excessive amounts. Retailers can fulfill consumer demand without running out of products or holding surplus inventory by managing inventory.

👉 Read More: What is Inventory Management? How Does it Work?

Effective retail inventory management leads to cheaper costs and a deeper understanding of sales trends in practice. The following tools and approaches for retail inventory management provide retailers with more information with which to operate their companies:

Building systems to log goods, accept them into inventory, track changes as sales are made, control the flow of goods from buy through final sale, and verify stock counts are all part of the inventory management system for a retail store. These systems' data assists you in reaching the advantages of inventory management in retail stores, such as decreased costs and larger profit margins.

The steps involved in retail inventory management are outlined below.

List all of the items you sell in one place with the following information:

If you sell online, you need to assist staff in identifying items. First, fill up your inventory record whenever you add new items. Update any information that changes, such as a vendor or wholesale cost. Establish inventory-entry policies, including who is accountable for it and when it should be done. A retail inventory management system's power should be unlocked by having rich data.

If you own a small company with only one store, keeping track of your inventory is simple. The items are almost certainly on sale or in the stockroom. However, omnichannel retailers and retail chains with several locations may have stock in warehouses, distribution centers, transportation, stockrooms, and shop shelves. There are additional particular places inside those destinations, such as sections, racks, and shelves. Missed sales and revenue are a result of misplaced and neglected goods.

Practices in retail inventory management help to avoid this. To fully or partially automate the mapping of your inventory, utilize radio frequency identification (RFID) tags, barcode scanners, and labels with category and department designations.

To guarantee that your inventory is accurate, you should count it on a regular basis. To avoid mistakes, consider shrinkage, defects, damage, and returns. Instead of starting from scratch, a retail inventory management system makes the system simpler since you simply have to double-check your information.

As a result, you may concentrate on deviations. The frequency of counting is determined in part by the complexity, scale, and kind of inventory management system used by your company.

Regardless, experts advocate counting inventories at least once a quarter or once a year. Some companies count particular elements of their inventory on a daily basis. Physical counting and cycle counting are two examples of counting procedures.

>> Explore More: Cycle service level - Definition and Formula

Sales and inventory data may be combined using retail inventory systems. This diagram depicts which products are turning over the fastest (a statistic known as sales velocity) and which are trailing. Use product data to determine when and how much to repurchase, as well as when to give discounts or promotions.

Set aside time to evaluate data and place orders so you don't fall behind on seasonal patterns or risk running out of stock. You may specify stock levels for particular goods and get reorder alerts using an electronic system. These levels should contain a buffer that enables typical sales to continue.

Review whether goods are sold out or at reorder points if you're using a manual approach, and add them to your shopping list. Purchases should be prioritized depending on their profitability, popularity, and lead time. Create a purchase order after that.

For a variety of causes, such as a cooling trend, obsolescence, or seasonal variables, product sales may fall short of expectations. If you provide markdowns, be strict about discounting and moving sluggish sellers so you can make money and create a place for more profitable items. Create a marketing strategy ahead of time to guarantee that you have adequate inventory on hand to fulfill demand.

You'll validate incoming orders and precisely record products into an inventory management retail store system during the receiving process. Any supplier error or damage in transportation might result in issues such as unexpected stock outages, overpayment to vendors, and deadstock if there is no defined method.

Verify that the contents of each delivery correspond to the purchase order. Count cartons and pallets, making sure the product type and numbers are correct and recording any errors, damage, or shortages. Any concerns should be followed up with the vendors.

Next, add the additional items to inventory counts and keep the goods. Price tags or bar codes may be added to the stock, depending on your demands. The easiest method of inventory management is continuous inventory management, which entails counting products as soon as they arrive.

You risk retaining unsellable stock or losing a chance to put a sellable item back on display if you don't have an inventory management strategy in place to handle client returns. When a customer returns an item, inspect it to determine if it is damaged or faulty, and then send it to the vendor for repair, write-off, or return. If the item is sellable, enter it into your inventory and set it where it belongs (in eCommerce inventory or a physical store, etc.).

Excessive stock wastes capital and reduces profits. Damaged commodities, erroneous delivery, and seasonal leftovers are examples of dead stock. To begin, make a list of things that fit into this category and remove them from stock. Appoint a location to store dead goods and dispose of them on a regular basis (weekly, monthly, or according to your business's needs). Ship pullbacks (items you may return to sellers for credit) as soon as possible.

Take note of any return shipment dates. Return damaged or faulty items to suppliers, or document and alert suppliers, as appropriate. You may sell the remaining to outlets, donate them, recycle them, or dispose of them, depending on your product line.

Select and track certain inventory management KPIs to measure the efficiency of your process. For retailers, inventory value, profitability, sell-through rate, and turnover rate are critical metrics.

These techniques can assist you in determining demand. This planning may be automated with inventory control software.

You can calculate the optimum order amount with this formula. Demand, ordering expenses, and carrying costs are all included in the calculation. The formula is:

EOQ = √ (2 × D × S / H)

D: demand in units S: ordering expenses per order, such as shipping H = holding costs, such as storage charge.

The quantity of stock you order as a safety net to avoid running out of stock is known as safety stock. This extra supply is kept on hand in case of inaccurate sales predictions or unexpected client demand.

Par level = safety stock + the minimal inventory necessary to meet customer demand

It's time to restock if the stock falls below the required level.

This method advises a store on how much stuff is for sale in monetary terms for a specific period of time. The objective is to assure sufficient supply while also producing positive cash flow. This is the formula:

OTB at retail cost = planned sales + projected end-of-period stock on hand, in transit, and on order - planned beginning-of-period inventory

Retailers can determine the reorder point or stock threshold which will prompt reordering, using the lead time and sales data for new products to arrive from vendors. This is the formula:

Reorder point (units) = (Average daily unit sales* average lead time in days) + safety stock in units

This technique, which avoids tying up money in inventory and storage expenses, was pioneered by Japanese manufacturers. With high-cost and low-volume commodities like vehicles and appliances, JIT is the simplest to deploy. When compared to the danger of stock-outs, the savings on low-margin along with high-volume items would not be enough to justify the additional complexity.

For accounting reasons, get one of these techniques to calculate the cost of your inventory and commodities sold. Taxes, profits, and the usability of financial reporting are all affected by both strategies. They are only used for physical inventory accounting. They don't expect you to know and track the age of every item you sell.

This strategy suggests you sell your oldest inventory items first. This method is one of the simplest choices to comprehend and utilize. This method follows a product's natural lifecycle: Older items are frequently sold first, before they deteriorate, become outdated, or lose value in some other ways. The most common option for retailers is FIFO, which is regarded to provide a better approximation of real-world business realities than LIFO.

This method implies that newer merchandise is sold first. These commodities are frequently more expensive than older stock, lowering declared earnings and taxes. LIFO has the danger of letting inventory sit on the books permanently, overvaluing or undervaluing it in comparison to market costs. LIFO accounting is less trustworthy since it is more prone to manipulation.

Retailers utilize this category's tactics to better analyze their own operations. They identify the best-selling products, for example, in order to prioritize them. These are also used by retailers to estimate their return on inventory investment and evaluate the worth of their inventory.

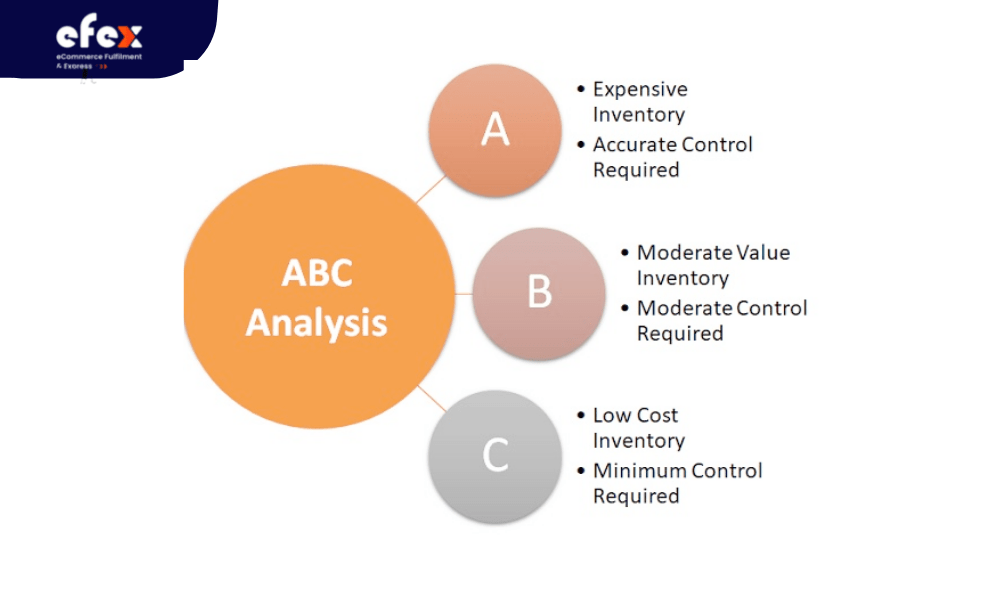

Inventory is divided into three groups using ABC analysis:

Retailers utilize this data to enhance how they manage inventory in each group, including how much they store and how they buy it. Marketing efforts and other strategic actions can be guided by ABC analysis data.

This approach, which refers to quick, slow, and non-moving evaluation, divides inventory into three categories, similar to ABC. The division focuses on sales velocity in this area (the level at which you can generate revenue). Price rises may be possible for fast-moving things. Likewise, a business owner may decide to phase out non-moving merchandise.

Because F items are closest to packaging stations and on the most visible shelves, an online merchant may structure a warehouse so that F products are the simplest and fastest to choose.

This method also classifies items based on demand fluctuation and sales forecasting complexity. X things have consistent demand, Y items have high fluctuation, and Z items have irregular and unpredictable demand. Retailers may also mix the ABC and XYZ systems to separate their inventory for more accurate ordering and stocking.

For example, your reordering rules for an AX item, which contributes significantly to your bottom line and has consistent demand, would likely differ significantly from those for a CZ item, which contributes the least to your bottom line and has unexpected demand.

Quality control is the goal of this segmentation process. This technique classifies commodities into categories based on how they were made or processed using similar raw materials. Retailers track details on items by batch or lot, including expiry dates, manufacturing location and date, origin, recall status, defective rates, and purchaser.

A grocery store chain, for example, wishes to keep track of all the yogurt's expiry dates in its inventory. To eliminate shade variance, a paint shop would ensure that each of the cans in a customer's order came from the same lot. In the meanwhile, some products, such as medications, require an audit trail.

This calculation involves how many gross profits merchants make on each dollar spent on inventory. Many retailers assess its value departmentally. This is the formula:

Gross margin return on investment = gross margin / average inventory cost

This formula informs a store how many times its whole inventory is sold in a year, and it's a good measure of financial stability and liquidity. There are a few options for determining this. One is the average inventory value/cost of goods sold. Add the initial and ending inventory amounts and divide by two to get the average inventory. The sales value/inventory value formula is the second formula. Inventory turnover rates average approximately eight across all forms of retail.

If your value is much higher or lower than your peers, you should consider using this approach. Steps like placing products on sale more aggressively and purchasing more or less of a product included. Considering your turnover rate also aids in the planning of orders for commodities with extended lead times.

Use these methods to estimate how much your consumers wish to spend. There are several qualitative and quantitative approaches to choose from. Moving average and time-series analysis are two typical quantitative approaches that include past sales and seasonality.

By combining different methodologies, predictive analytics software can conduct this type of predicting. Having a clear understanding of demand may help you increase profits by assisting you in determining personnel, buying needs, and the best inventory to hold.

This technique entails checking a certain department or business location on a regular basis. Spot checking is a useful way to catch errors in inventory operations before they turn into bigger concerns. Managers should do inventory spot checks on a regular basis, particularly after implementing a new strategy or making a significant change to the inventory management retail strategy.

This process compares financial data to physical inventory counts. In a formal audit, an accountant checks the physical count. During audits, companies routinely halt operations to guarantee that no products are moved. Physical inventories take a lot of resources, effort, and preparation for big firms. A physical inventory, on the other hand, is an effective approach to preventing inventory shrinkage.

This method requires stores to count a portion of their inventory on a daily basis. Although retailers normally undertake a comprehensive physical inventory on a regular basis, you don't need to halt operations for this kind of count. Cycle counting is ideal for businesses with a large inventory that can't afford to stop operations to do comprehensive physical inventory inspections.

This method may be troublesome for organizations who are unable or unwilling to use inventory management software. To cycle count, businesses must keep meticulous records.

Inventory management best practices help retailers achieve better stock accuracy, reduced costs, decreased shrinkage, and bigger profits. Follow the guidance of inventory specialists and strive to satisfy industry standards.

Make every effort to order the correct amount of product at the right time to meet demand and satisfy consumers. Set data-backed levels for your safety and par stock, understand reorder thresholds, improve order sizes with economic order quantity (EOQ), and plan purchases using the open-to-buy approach.

Request accurate lead times and share sales and product projections with vendors. Monitor service levels from suppliers, such as the proportion of orders that are completed and fulfillment timelines. Talk with vendors that need to better and outline the specific steps needed to achieve your requirements. Prepare for contingencies by determining alternate sources for your most critical products in case your primary supplier fails to deliver.

Keep an eye on your KPIs. Applying ABC, FSN, or XYZ analysis, determine which goods are your best and worst performers. Understand client demand indications and seasonal swings, as well as your turnover rate and GMROI. Make a concerted effort to increase the accuracy of your client demand and sales projections.

Always continue to attempt to increase the efficiency of every aspect of your inventory management. Organize your warehouse and arrange it wisely. Other strategies to increase efficiency are listed below:

Conduct inventory audits and counts on a regular basis. Set performance targets for your employees and train them in inventory management. Create an environment where accuracy is valued.

You can automate numerous processes and make an immediate approach to achieving accuracy and efficiency by applying technology including retail inventory software for small businesses as well as big companies. You may link your point-of-sale (POS) system with inventory management by using the correct technology, which eliminates the need for manual data input, reducing mistakes and generating richer data. An automated system may also deliver stock alarm messages and make inventory coordination in many locations easier.

Effectively managing your retail inventory is critical for meeting customer demand while minimizing costs from overstocking or shortages. This requires tracking stock levels, optimizing order quantities, implementing robust processes for purchasing, receiving, and returns, as well as leveraging reporting and analytics.

Partnering with a 3PL like EFEX can boost inventory efficiency through warehousing, real-time visibility, and seamless integration with your sales channels. Our fulfillment services provide the infrastructure and retail expertise to help you scale while reducing out-of-stocks, overhead, and waste. Contact EFEX today to learn how our customized solutions can set your inventory management on the path to increased sales and profitability.