More Helpful Content

Keeping track of inventory as a multichannel retailer, wholesaler, or e-commerce firm may be challenging. However, businesses can now use systems, inventory processes, and technologies to help them streamline their supply chains. Inventory control solutions allow you to track your inventory effectively and correctly. This article will explain what inventory control is, as well as its advantages. It will also explore certain inventory control process and techniques, as well as give ideas for improving the inventory management systems.

Inventory control, also known as stock control, refers to the process of a company's inventory levels being managed, whether in their own warehouse or across many locations. It includes product management from the moment they are in stock through their end target (preferably, customers) or disposal (not ideal). The inventory management system tracks their usage, movement, and storage as well.

Inventory control refers to maintaining track of your stock levels to ensure that you have the right amount of each product available. Inventory management will help you keep track of your purchase orders and maintain an effective supply chain. Forecasting systems can be implemented, as well as the ability to define reorder points.

Controlling inventory can include:

So, what is the purpose of inventory control? The overall purpose is to maximize profitability while keeping as little inventory in your warehouse as possible. This must be done without compromising the customer experience. While manual inventory control is possible, there are automated methods that can manage your stock levels for you and help you avoid pricey human mistakes.

Inventory control is common in inventory management in that they both deal with aspects of inventory. Inventory control operates with inventory that is already in the warehouse of a distributor. It requires an understanding of your inventory's contents as well as its location inside your warehouse. It guarantees that inventory is in excellent working order and is organized in a cost-effective way. The business procedures of product replenishment and forecasting are included in inventory management.

To minimize stockouts or storing too much inventory, management includes determining when to restock items and how much to order. It guarantees that the proper inventory is at the proper spot, at the right time, and in the exact amount. When you strengthen your inventory control, you may accomplish better inventory management.

Inventory control provides a number of advantages, including cost savings and improved customer satisfaction. It also helps your business save time, money, and resources. Your firm may see a substantial increase in sales, but without inventory control, your profitability may suffer. Here are how your business benefits from inventory control:

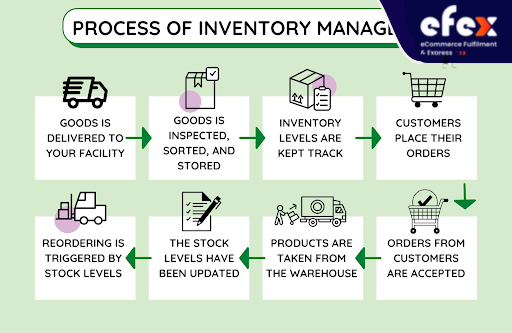

Managing inventory necessitates the creation and implementation of a basic set of procedures. Once in place, these procedures reduce the chances of inappropriate inventory management. Besides, they also should be included in any warehouse manager's job. At first, you must comprehend the phases that inventory flows through. before you can design your strategy. All inventory plans are based on the eight phases of inventory process management. These are the inventory processing.

The following are 8 inventory process steps:

This is where things are first added to your inventory.

The product is checked, sorted, and kept in storage. Depending on how much room you have, you can use dropshipping, cross-docking, or another method.

Monitoring inventory levels can be done through inventory cycle counts, physical inventory, or software for perpetual inventory.

Customers can purchase from you in person or online.

In your POS system, this is most likely an automatic action. If you are using dropshipping, this is the time at which you send the order to your provider.

These items are located using SKU numbers, packed, and sent or delivered to the consumer directly.

The levels of stock will be changed automatically via perpetual inventory software. When you do a physical inventory, you can also input every sale manually or detect changes.

Determining your order quantity for each item you sell will help you streamline this process and ensure you have enough inventory to meet demand. The JIT inventory approach relies heavily on this.

With well-managed inventory control processes flows, these eight phases may be completed more quickly. By monitoring and examining all inventory processes and procedures, every step can be improved. To raise your profit and lower your costs, you may minimize waste, find defects, and reassign resources as needed at any step.

Inventory Management Process Map a flowchart that displays each phase of your inventory management process is an inventory control process map. Even though 8 stages are relatively common, other factors are detailed to your company. You may always be ready for any shifts in demand or supply by planning out all steps and possibilities.

For instance, once an order arrives but your stock is running out. You'll have to make a decision. The best way of tackling the problem should be included in your inventory control procedure map. It might involve putting on backorder or refunding the buyer. You may even mention on your mapping that you really do both depending on the item's worth.

Inventory management techniques refer to the solutions that help you keep track of your stock. These range from product ordering to shipping techniques, and each has its own set of advantages if implemented correctly. Inventory management is critical to making the most money and making sure that you can complete your customers' purchases.

Implementing effective inventory control methods can assist assure a company's financial health and that its products satisfy the demands and expectations of its consumers. Taking stock is just the act of identifying what you have and where you keep it in order to assess it. Not every business or stage of a company's growth and development needs the same inventory control methods. Some approaches are very complex, especially for small businesses.

The 4 main inventory management techniques:

These tools ensure that your inventory of items is adequate to meet customer needs. They each have their own set of advantages depending on the type of business you run. Here's a basic summary of each.

The Kanban technique of managing inventory is a system for keeping inventory levels to a minimum. It is organized around "bins" that segregate the various materials needed in the manufacturing process. The lean manufacturing paradigm or the JIT model includes this as a key component. It only permits you to maintain just enough inventory available to meet current requests. When you place a fresh order, you'll get a shipment of the parts you'll need to complete it.

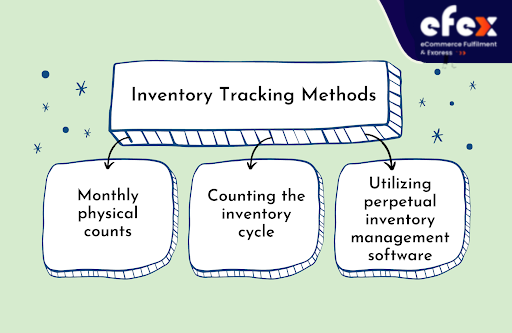

Tracking each individual product is among the most vital things you can do to manage and control your inventory. What are the 3 inventory control systems (inventory tracking)? The following are the three most basic inventory tracking methods:

The most time-consuming and ineffective technique of inventory tracking is manual inventory counting. All activity must come to a halt, and teams must be formed to walk across your storage and account for all inventory. This data is saved in a spreadsheet or in specialist software. Although this strategy is an excellent beginning point, it may become overly complicated as your inventory grows.

In miniature, cycle counting is similar to inventory counts. Rather than manually calculating all of your stuff every month, you only count the ones that are most valued every several days. The above allows you to check up on the things that are really important to your business and respond more quickly if an issue arises. It also allows you to count inventory without having to stop what you're doing. It should, however, be used in combination with the other inventory tracking technique because you won't know your complete inventory levels.

Investing in permanent inventory management software is the best approach to keeping track of your inventory. This program is updated automatically anytime items are delivered, sold, or deemed lost or damaged. You'll always have such current inventory counts at your fingertips, allowing you to adjust the course and meet customer demands before any issues arise. The only one downside is that there is an extra charge because there is a fee associated with it.

There are several strategies to optimize inventory management and make the most of your stock. The following are several options:

The inventory management will improve as your relationship with your providers strengthens. They can assure you're always supplied if you convey market shifts and product demands on a frequent basis.

Professional inventory managers are typically preferred to somebody with multiple tasks. This individual can keep track of supply problems and respond more promptly than you can. The key element in determining an inventory manager's pay is inventory management.

Reordering products can be better scheduled if you understand how long you'll have to wait. These will assist you in avoiding problems with customer demand.

The more stock you have, the more difficult it becomes to manually keep track of everything. Inventory management software can help you save time and money while reducing workloads.

Effective inventory control process is critical for every business. It helps you to improve your cash flow and save money on managing inventory. You can build an inventory processes control strategy that tracks your assets in real time by utilizing inventory control software. Giving you access to and control over your inventory.

Even if your company is small, you have the option of using either a periodic or perpetual inventory system. A perpetual inventory system, on the other hand, is clearly a better solution if you have a huge volume of goods or more complex operations. Good software helps you with inventory control operations and streamlines the process.